Educational Guide:

Introduction to Leak Detection

Introduction to Leak Detection

Leak detection is the process of testing empty plastic blow-molded containers for leaks and defects. Leak detection helps:

Every container that is produced has the potential to have leaks. By taking the time to incorporate leak detection into your production line, you are protecting your brand and providing the end-user with a high-quality product. Leak detection is a critical step in the manufacturing process that helps identify issues that lead to product leaking or contamination before they get to the consumer.

Empty plastic containers are manufactured in high volume to keep up with demands. It is inevitable that some containers will have defects that will cause leaks once the bottles are filled and shipped. Inline leak testing equipment tests plastic bottles as they move through the production line and automatically rejects those with defects.

By performing empty container leak testing – you can identify issues before bottles make it further down the production line, minimizing the potential of recalls associated with bottle quality.

Leak testing provides a functional test and verifies that each container will seal and hold pressure. Containers that have been leak-tested will provide a variety of benefits including:

Leak detection also supports many of the market trends that are being implemented, including:

Consider the value of your inventory. Reflect on past quality issues you have experienced and ask yourself, “is my product leak tested and protected?”

Most blow molders use a one-step or two-step process to manufacture PET containers. The manufacturing method used in your molding facility determines the type of bottle leak testing equipment you require. You should also consider the bottle size and shape, as well as your production speed.

Both bottle molding processes produce high-quality containers, but neither method can guarantee your bottles will be defect-free

By introducing a pressure decay leak test procedure manufacturing companies can better guarantee a high-quality product, free of defects.

To learn more about blow molding, check out our Leak Detection Fundamental Series:

Bottle leak testing equipment is a valuable investment.

Many manufacturers rely on spot-checking by employees for PET bottle quality verification, but that is not always enough, especially if small leaks are present.

To learn more about PET container testing, visit: PET Leak Testing for Bottles

A wide range of defect types can be found within the mass scales of PET bottle production. When performing a bottle leak test, ALPS seeks out the following types of defects:

A wide range of defect types can be found within the mass scales of PET bottle production. When performing a bottle leak test, ALPS seeks out the following types of defects:

To learn more about different defect types, check out our blog: What Causes Different Plastic Bottle Defects and How to Prevent Them

Even the smallest of container leaks can cause challenges for bottle manufacturers. It becomes an even larger issue if leaks are identified after the containers reach your customer and end-users.

Testing empty containers for leaks and other defects is the most effective way for bottle manufacturers to ensure product quality.

Having a leak tester on your line is a great first step to ensure the container you are producing meets set quality standards – before it reaches the end-user.

How do you know what kind of leak test options are out there and which one is the best fit for my product? The answer depends on the type of product you are testing and wherein the process you are testing it.

First, you need to determine is if you want to test filled containers or empty containers.

First, you need to determine is if you want to test filled containers or empty containers.

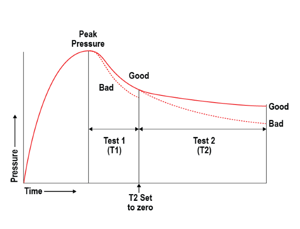

If you are testing empty containers that are not required to have a vacuum seal, then pressure decay is the most efficient method.

Pressure decay is also beneficial in applications where the lack of container stability allows the possibility of an empty container to collapse during testing.

To learn more about the pressure decay leak test method and empty containers, read our blog, Pressure Decay Leak Test: Why it is ideal for empty container leak testing.

If you are testing a filled container or one that requires a vacuum seal, then the vacuum decay method might be your best solution.

Vacuum decay testing is a non-destructive test that detects leaks in nonporous, rigid, or flexible packages. This method ensures that packaging that contains items such as food or beverage are safe from possible container leakage after being filled and sealed.

Linear leak testers are ‘in-line” defense systems for non-destructive leak testing used for empty containers.

Linear leak testers are ‘in-line” defense systems for non-destructive leak testing used for empty containers.

Available as single or multi-test stations, these solutions are configured to test containers that are “in-line” on a conveyor system.

As containers move along a bottle conveyor system, a stationary or moving test head uses either vacuum decay or pressure decay to leak test each bottle.

Linear leak testers are flexible solutions that are ideal in a range of industries, from food and beverage to pharmaceuticals.

When tailored to the application, linear leak testers typically offer a more flexible and lower-cost approach for leak testing plastic bottles.

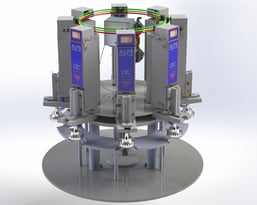

Rotary leak testers inspect containers as they travel around a turntable, using either pressure decay or vacuum decay leak testing methods.

Rotary leak testers inspect containers as they travel around a turntable, using either pressure decay or vacuum decay leak testing methods.

Test heads check each bottle for leaks, and will automatically reject any defective containers as the bottles exit the machine.

Rotary leak testers are typically configured with multiple stations and are used to test empty containers of all sizes, ranging from small pharmaceutical vials to extra-large bottles.

Rotary leak inspection equipment provides the accuracy and speed required for high-volume leak testing applications. Containers are continuously fed through the rotary leak tester, with the speed and test time determined by the number of leak test stations.

Integrated leak testers are custom designed to be integrated into existing equipment and provide an alternative to purchasing and installing a full leak testing system into a production line.

Integrated systems are used to test empty and filled containers of various sizes such as pharmaceutical vials, beverage bottles, food packaging, automotive oil bottles, and much more.

When deciding which leak detector is right for your application, start by identifying a system that can handle these 4 things:

To learn more about leak detection systems and application types, check out our blog: What type of leak inspection system is right for my application?

Additionally, factor in bottle handling:

Consider these factors, and for guaranteed success, now and in the future, partner with a company that manufactures multiple solutions that can be tailored for your applications and are supported by a service team that is available 24/7.

To learn more about what factors to consider in a leak detection supplier, read our blog, Comparison: How ALPS Inspection leak testing equipment stacks up against the competition.

Blow molders who manufacture plastic bottles for the food and beverage industry need to avoid product loss.

Leak testing bottles before they’re filled can ensure that defective bottles never reach the filling line. ALPS Inspection leak testers automatically reject defective bottles and machines can test up to 1200 bottles per minute.

Our food and beverage leak testing machines use pressure decay to test the integrity of all types of beverage bottles, including those with more complex, stylized shapes.

Loss of product is a concern for most manufacturers of household products, but when hazardous materials are involved, the integrity of blow-molded or injection-molded bottles is paramount.

Manufacturers of containers used for household, personal, automotive, or industrial purposes rely on leak testers to ensure the integrity of their containers – and prevent costly leaks.

Consumers will not buy pharmaceutical products from companies they cannot trust.

A big part of building trust with consumers is ensuring the integrity of the packaging that products come in.

Pharmaceutical manufacturers stand to lose a lot of money if bottles leak and lead to product loss. ALPS leak testers help pharmaceutical and medical manufacturers prevent product loss by automatically rejecting defective bottles.

Choosing the right blow molder partner can make or break your next product. While it may seem like a straightforward process, manufacturing containers to your specifications consistently and up to your quality standards is no small task.

How to select the right leak inspection system

There are several details about the production process that affect the speed & quality of your production process. For example:

Key information brands need to provide a blow molder to get the most out of them

Understanding what information blow molders will need from you will help you become informed and help pick the best blow molding partner for your needs. Key information usually includes:

To learn more about how to select the right blow molding partner, visit our brand manager page that educates and walks you through key pieces of information to select the right partner for your needs.

If you are using Post-Consumer Recycled (PCR) material, also known as rPET plastic, in the blow molding process, there will be inherent risks. While using PCR throughout the blow molding the questions then arises, “How do I protect my product while increasing PCR content?”

Using PCR can cause pinholes and leaks in containers. During the blow molding process when the walls of the container are stretched, particles of contamination can cause weaknesses resulting in holes in the container wall. The number of defects will depend on two things:

Leak detection is a guarantee that only containers meeting quality standards make it to the end-user. 100% in-line inspection will catch pinhole leaks, neck surface deformities and height irregularities, including short shots.

Commitment to sustainability does not have to mean sacrificing product quality. Leak inspection provides the assurance you need to keep up with market trends, including increased PCR content.

Leak detection and Post Consumer Recycling (PCR)

Inspection Insights Blog

A collection of insightful content written by the leak detection experts at ALPS Inspection. The collection includes practical tips, best practices, and how to’s on leak detection and package integrity.

Read through our Leak Detection Fundamentals collection to learn about the best method and machines for leak testing your container type.

Leak Testing PET Containers Produced by the Two-Step High Speed Stretch Blow Molding Process

Please fill out a form confirming your product details and plastic bottle leak detector requirements.