Find the Right Solution For You

Let us help you find the right solution for your needs.

Let us help you find the right solution for your needs.

Enter your information below and let us help you find the right leak testing equipment for your empty, rigid containers.

If you have any questions, please don’t hesitate to contact us. We’re here to help!

Results will display here...

.jpg?width=800&height=800&name=QuickCheck_TOP%20FRONT%20RIGHT%20(1).jpg)

QuickCheck Linear Leak Testing System

Machine Type: Single station linear, indexing conveyor

Speed: 2 to 200 CPM (120 to 12000 BPH)

Container Size: 0.3oz to 5gal. (10mL to 19L)

Features: Servo driven indexing vacuum conveyor, color touch screen. General purpose unit, requires transfer of bottles to/from leak tester conveyor.

RS-S Linear Bottle Leak Detector

Machine Type: Single station linear, moving head

Speed: 10 to 150 BPM (600 to 9000 BPH), depending on bottle size and conveyor speed

Container Size: 1 to 64 oz. (3cc to 2L)

Features: Servo driven linear slide, encoder wheel to match to conveyor speed. No tooling, bottle backlog or bottle transfers required. Best for hard-to-handle containers.

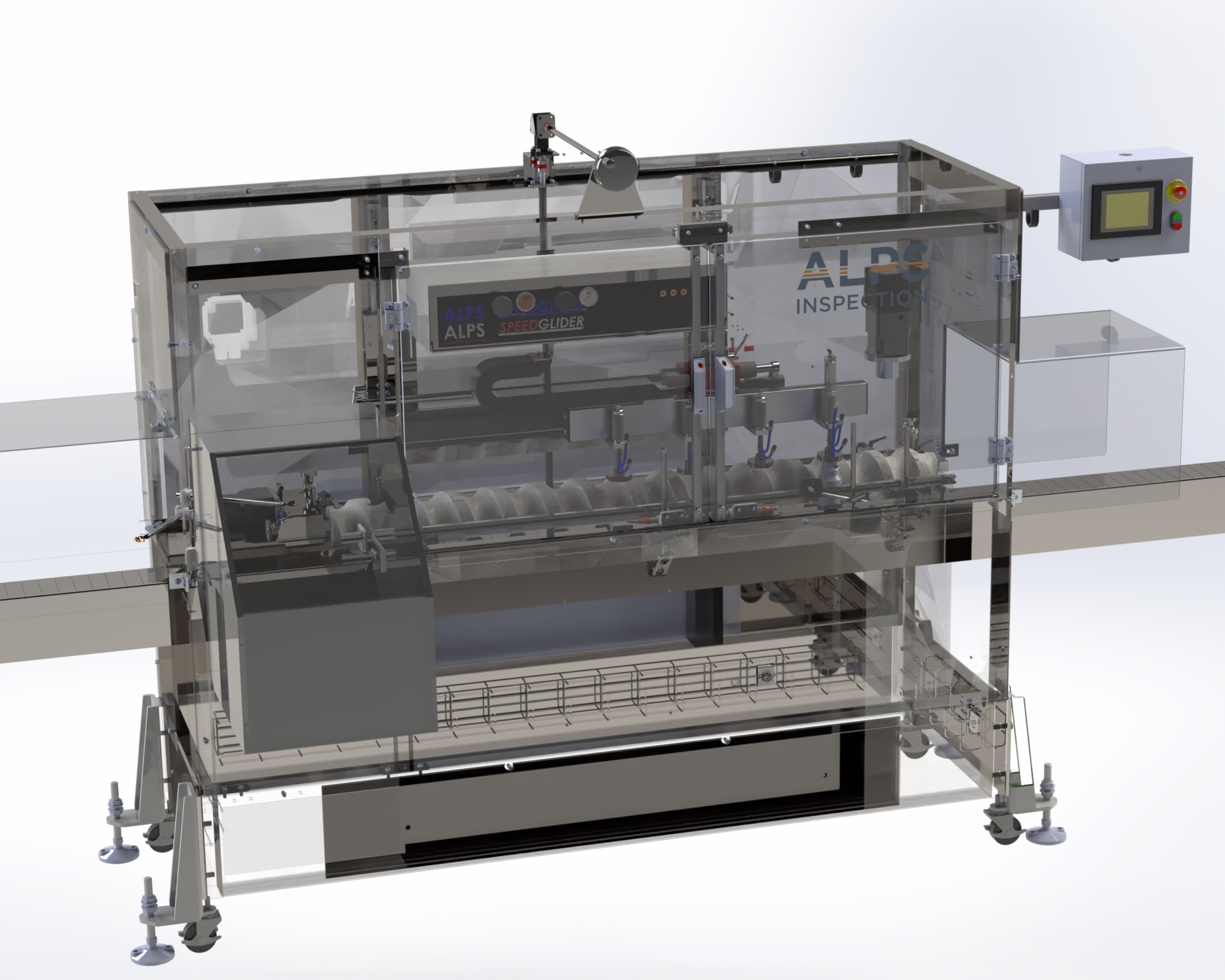

Speed-Glider Multiple-Station Moving Head Linear Leak Detection System

Machine Type: Multi-Station Linear, Moving Head

Speed: 20 to 500 BPM (1200 to 30,000 BPH), depending on bottle size

Container Size: 4 to 300 oz. (100mL to 10L)

Features: Servo driven linear slide, positive Timing Screw handling, multi-channel high speed PLC, color touch screen. Lower cost alternative to small rotary leak testers

FlexPitch® Multi-Moving Head Leak Tester

Machine Type: Multi-station linear, moving head

Speed: up to 250 BPM (depending on bottle size)

Container Size: up to 350 oz.

Features: 2, 3 or 4 multi-moving heads, high speed, no timing screw, fast and tool-less changeover, wide range of bottle, no line modification, mounts over existing conveyor

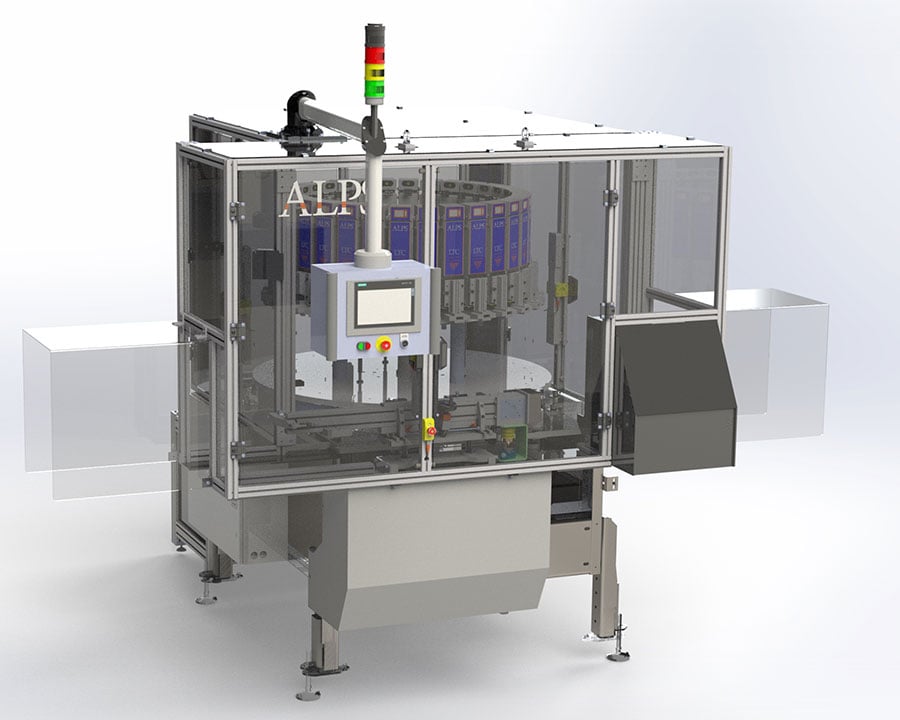

NexGen Rotary Leak Detector for Empty Containers

Machine Type: Rotary continuous motion, 4 to 30 stations

Speed: 50 to 1200 BPM

Container Size: 8 to 300oz. (0.2 to 10L)

Features: "LTC" pressure or vacuum decay test circuits, Quick-Lock No Tools change parts, color touch screen

FlexPitch® Duo Leak Testing System

Machine Type: Dual-statin linear, moving head

Speed: 75 to 250 BPM (4500 to 15000 BPH), depending on bottle size and conveyor speed

Container Size: 1 to 59 oz. (3ml to 1.75L)

Features: Created to support faster lines and smaller container testing. Dual independent moving test heads operate in the same space, resulting in a smaller footprint. Fast and simple installation.

BottleStop™ Multi-Head Leak Testing System

Machine Type: Multi-station linear, bottle stop

Speed: up to 65 CPM (depending on on conveyor speed, container size and detectable hole size)

Container Size: 4oz to 6gal

Features: Designed to seamlessly integrate with your existing conveyor system, it ensures consistent quality control at speeds of up to 65 CPM (containers per minute).

BenchPlus Manual Leak Testing System

Machine Type: Manual single-station, benchtop

Speed: Up to 20 CPM

Container Size: 1 oz to 5 gal

Features: Compact benchtop leak tester for manual testing. Adjustable over a wide range of container sizes. Adjustable backstop for repeatable container placement. Color touchscreen HMI with advanced capabilities to categorize defects and report results.