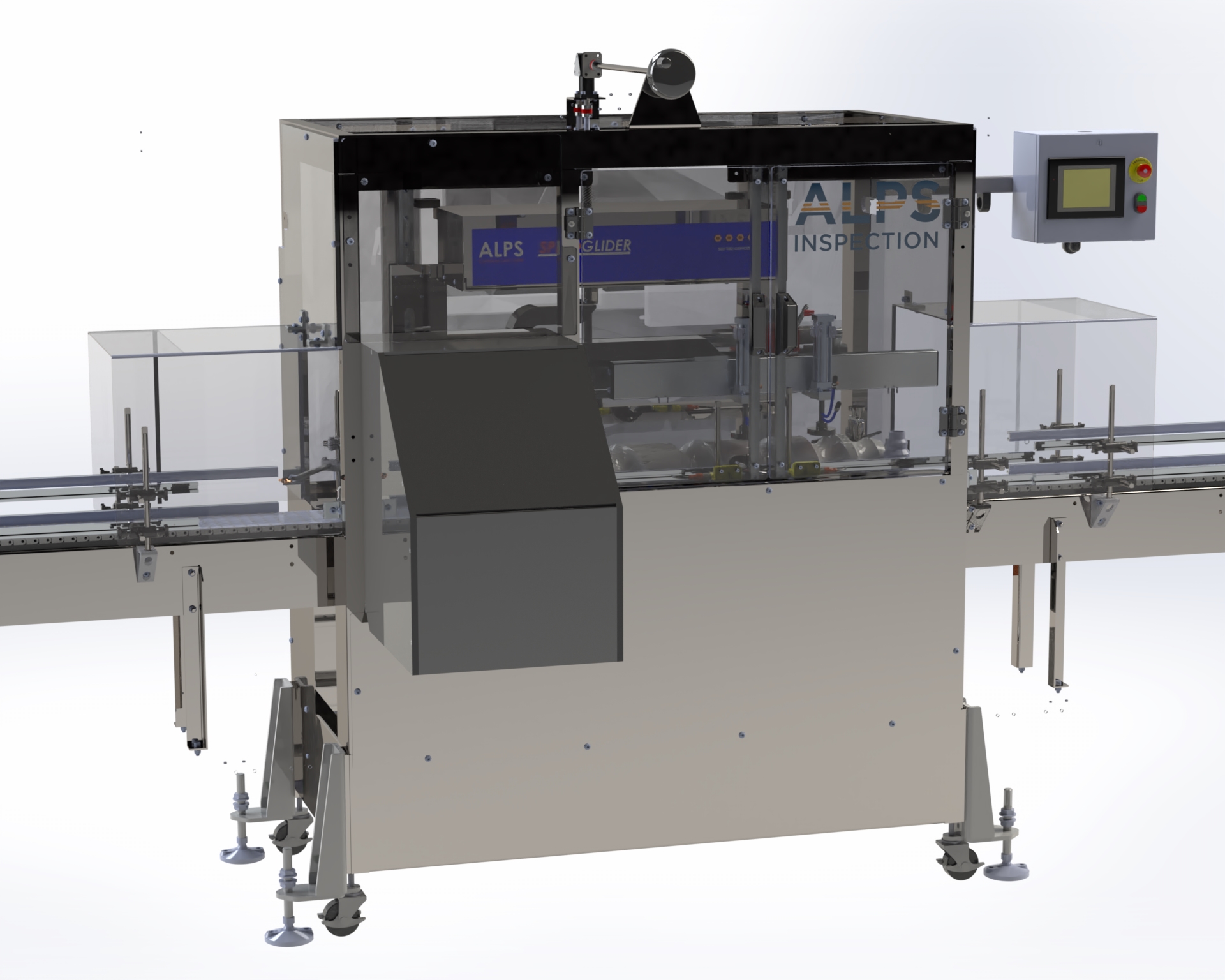

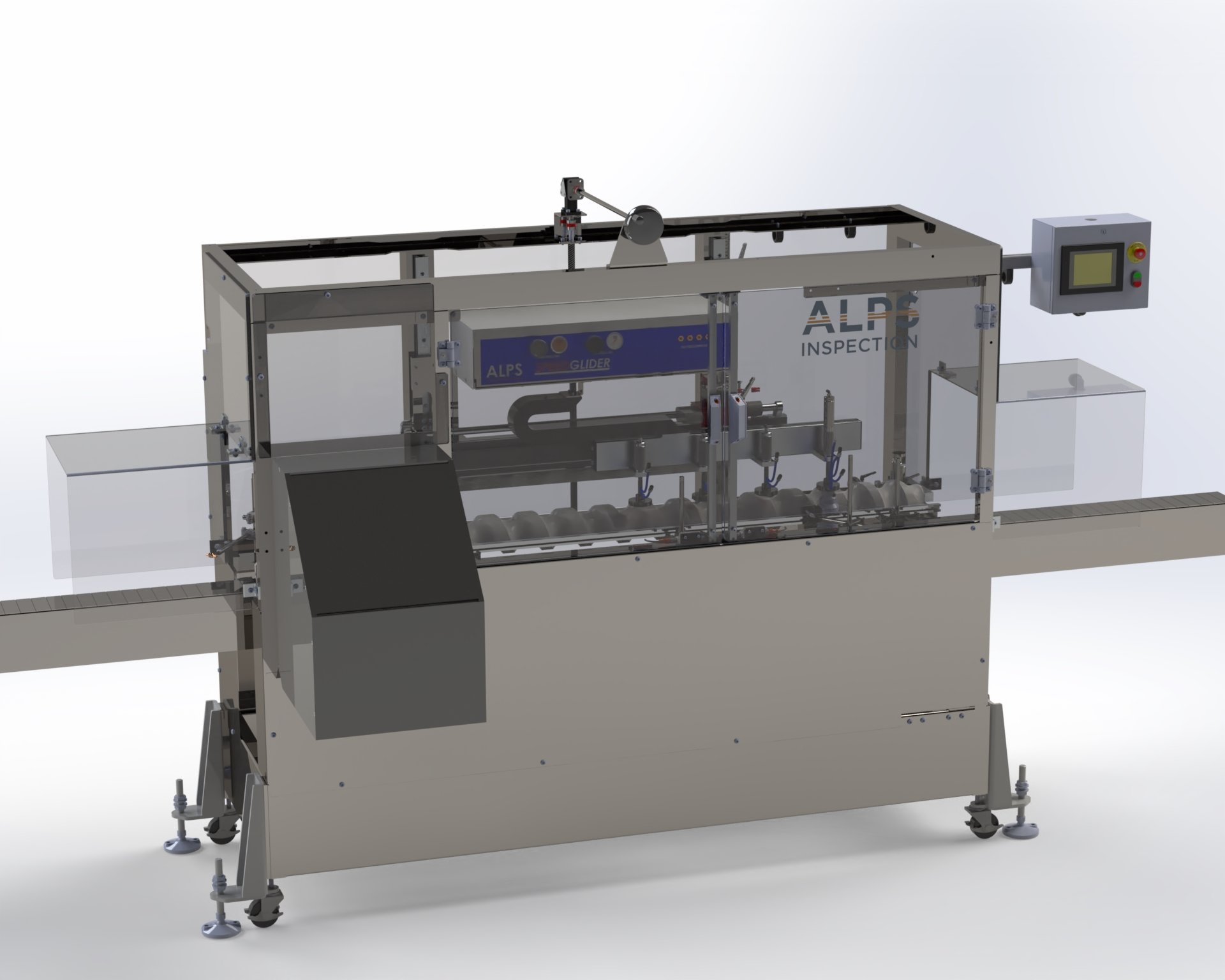

Speed-Glider Multi Station Moving Head

Linear leak tester

Linear leak tester

The ALPS Inspection Speed-Glider is a multiple-station, continuous-motion, high speed linear leak test system for empty containers. The Speed-Glider is designed for inspection speeds up to 500 containers-per-minute, CPM, (30,000 containers-per-hour, CPH).

Positive container handling and control is achieved throughout the leak test cycle through the use of precision timing screws for each container size. (The timing screw regulates the container positioning, and only a single sensor is used in the leak test area to verify the presence of containers. The use of this single change part greatly simplifies setup and changeover, while ensuring optimized performance of the leak tester.

The Speed-Glider is designed to conveniently install onto existing tabletop conveyor systems, in many cases eliminating the need for container transfers between conveyors.

Test probes extend to form a leak tight seal on each container, and test each container using the pressure decay leak test method. If a container fails the leak test, it is ejected as it exits the Speed-Glider’s timing screw, down a chute and into a user-supplied bin.

This leak test equipment is controlled by a multi-channel PLC and color touch screen interface with an intuitive, icon-based menu structure. Standard features include an integrated self-test feature for each station.

Watch the video below to learn more about the features and benefits of the Speed-Glider.

Common applications for empty container inspection using the Speed-Glider moving head leak tester include:

TEST PROBES

QUICK-CHANGE TIMING SCREWS FOR POSITIVE BOTTLE HANDLING

Speed Glider with 2 Test heads

Speed Glider with 4 test heads

To discover your ideal leak detector, fill out a form confirming your requirements and an ALPS expert will be in touch.