Leak Testing Equipment

Monitor and improve plastic container production.

Monitor and improve plastic container production.

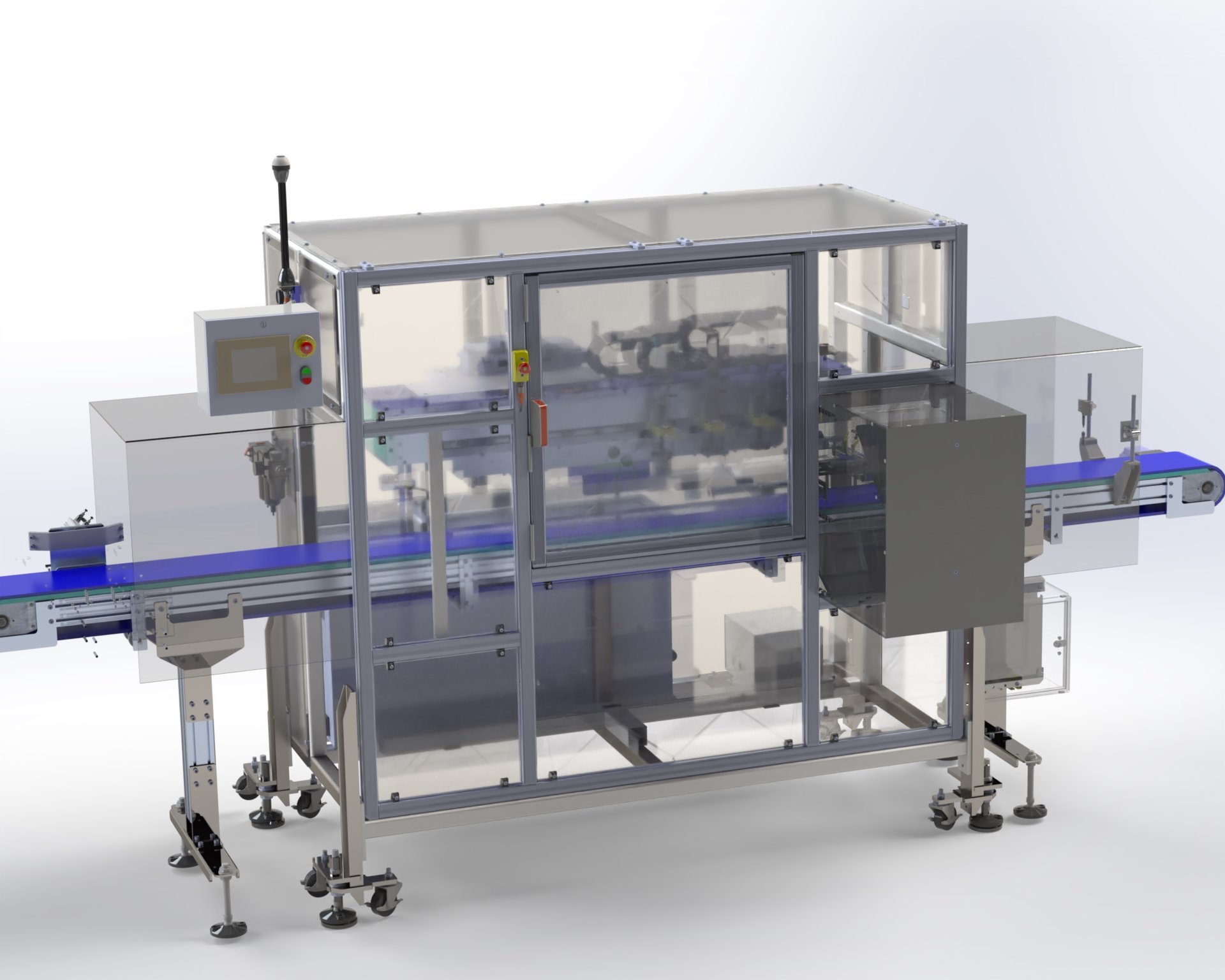

Split seams, weak seals, and other plastic packaging issues do not just result in leaks. They can lead to contamination that affects product integrity and can affect your brand. Empty plastic container leak inspection equipment detects defects along the bottom, sidewalls, and neck of plastic containers. Available as separate tabletop units or integrated into your production line, ALPS Inspection systems perform leak and integrity tests without interruption to your production line.

Test from a dozen to a hundred bottles-per-minute and keep your manufacturing processes running smooth and efficient while ensuring packaging quality.

Empty plastic container leak testing systems from ALPS include linear in-line testing systems that include single or multi-testing stations for bottles of various sizes. Choose the one that fits your production needs.

FlexPitch® Multi-Station Moving Leak Detector

NexGen Rotary Leak tester