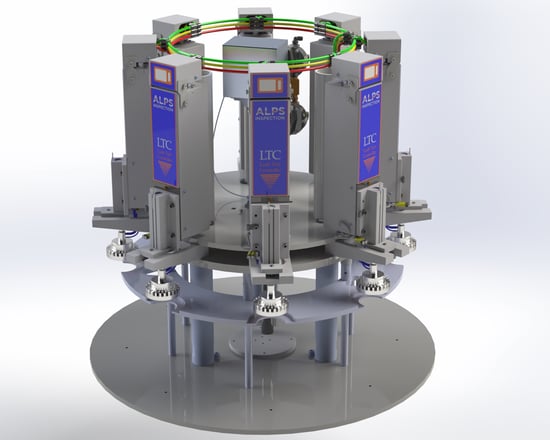

Integrated Leak Testers

Customized leak detection for your existing equipment.

Customized leak detection for your existing equipment.

Integrated leak testers are custom designed to be integrated into existing equipment and provide an alternative to purchasing and installing a full leak test system into their line. They are used to test empty and filled containers of various sizes such as pharmaceutical vials, beverage bottles, food packaging, automotive oil bottles, and much more.

Leak detection machines are available in rotary leak testing and linear leak testing configuration and use one of two methods for testing empty and filled containers:

Contact us to discuss options for customized integrated leak testers.

ALPS Inspection provides custom units designed for leak test integration within other equipment. Our integrated leak testers are built to our customers’ unique specifications and engineered for compatibility with their existing equipment.

These custom units help customers save time and money and can be integrated with equipment such as:

We offer a full line of integrated leak testers, making it easy to find the right device for your needs. Our family of leak test integration solutions includes:

Request a quote on the integrated leak testing unit you need, or contact ALPS for more information.

ALPS specializes in the design and manufacture of state-of-the-art leak detection machines for plastic containers of all types. We have established partnerships with numerous industry OEMs to ensure reliable leak test integration between our equipment and theirs.

If you produce or otherwise work with plastic bottles and/or other plastic containers, chances are good you use equipment manufactured by one of our OEM partners. If you do, you will have no problem installing one of our integrated leak testers into your system. Even if you do not, our devices are still remarkably easy to install and use and should present no significant obstacles for full leak test integration.

To discover your ideal leak detector, fill out a form confirming your requirement and an ALPS expert will be in touch.