FlexPitch Multi-Head Container Leak Testing System

Offering 100% inspection for leaks and top seal surface defects.

Offering 100% inspection for leaks and top seal surface defects.

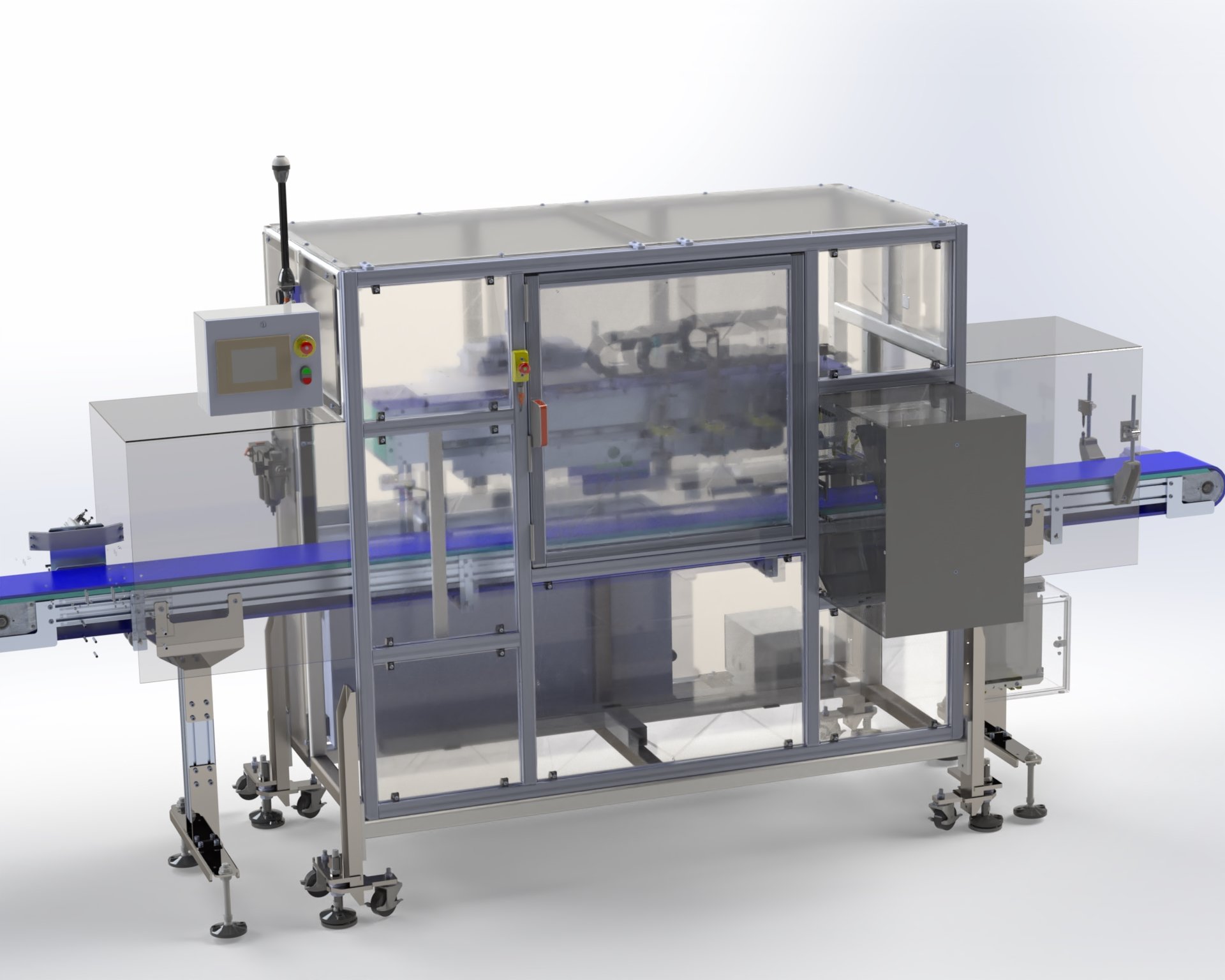

Standard Frame Size

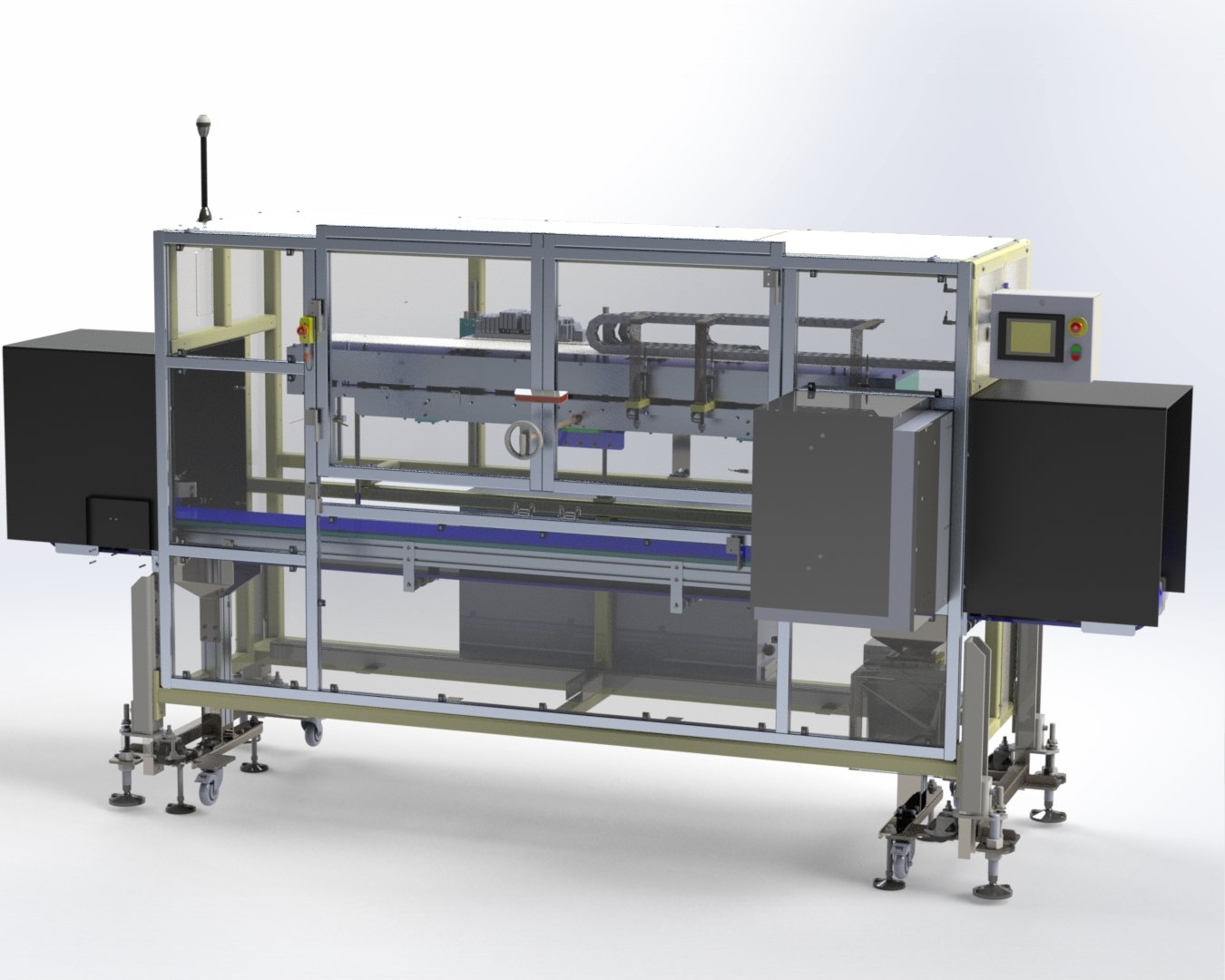

Extra Large Frame Size

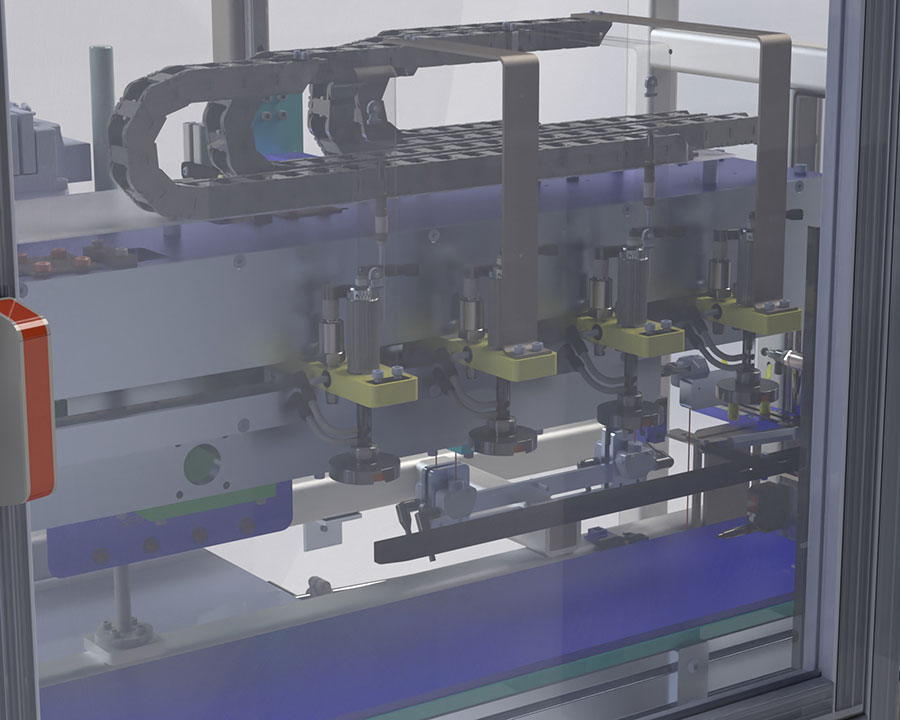

Test Heads

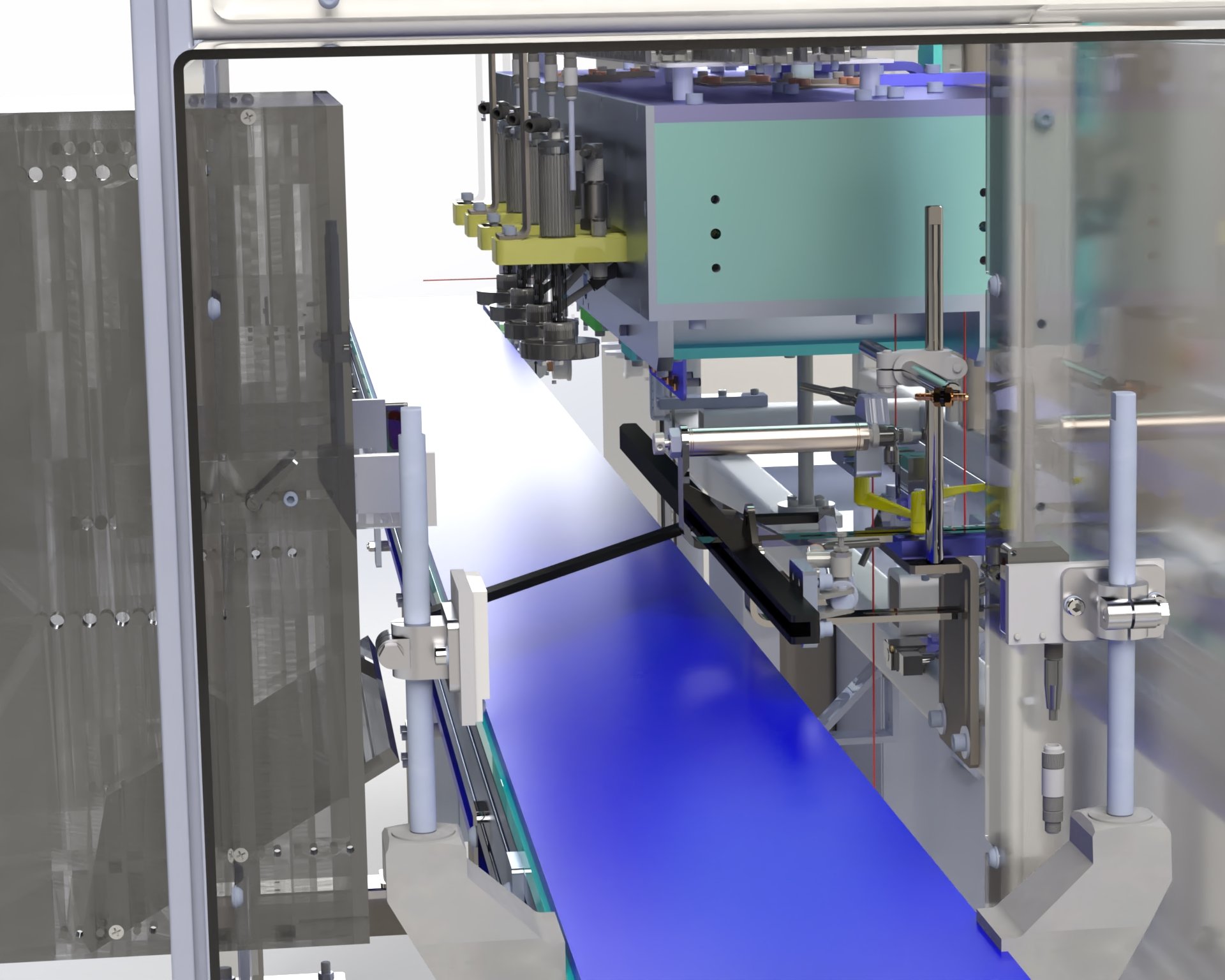

Conveyor

The FlexPitch is a fast, tool-less, multi-moving head leak tester with the flexibility to test a wide range of empty containers. The machine operates without a timing screw, which significantly reduces the cost for tools, as well as, the time it takes to perform a changeover. This results in a reduced cost to run additional container types.

The innovative design maximizes flexibility as test heads can be pre-set to the required pitch enabling fast changeover between containers of varying diameters. It is particularly suitable for difficult to handle container shapes including:

Features of the FlexPitch include:

Gain simple vision capabilities for specific defects with ALPS Inspection’s new Vision Option.

Equipped with a single Omron camera (with an optional 2-camera system for dual-neck containers), the simple Vision Option identifies issues including:

The leak tester seamlessly manages the container tracking. With a camera mounted at its infeed, the leak tester performs the following sequence:

The Omron controls are integrated into the FlexPitch leak testing system, so there’s no additional footprint.

An easy-to-use Vision Option eliminates the need for a costly, complex vision inspection system when you are only struggling with one or two defects. With an adjustable camera mount for easy changeover and industrial PC connected to a 15” HMI to handle vision processing, the Vision Option offers quick results for simple applications.

Interested in the Vision Option but not for FlexPitch? Contact us about platform availability.

Common applications for empty container inspection using the FlexPitch multi-head moving head leak tester include:

Looking to leak test smaller containers? The new FlexPitch® Duo might be the right choice for your production line. Learn more about FlexPitch Duo now.