What You Need to Know About Detecting Container Leaks With Pressure Decay Testing

Bottle Defects Are Random. Protect Your Inventory. Protect Your Brand.

Even the smallest of container leaks can cause challenges for bottle manufacturers. It becomes an even larger issue if leaks are identified after the containers reach your customer. Testing empty containers for leaks and other defects is the most effective way for bottle manufacturers to ensure product quality.

While vacuum decay testing is a popular testing method for many manufacturers, it is typically not ideal for empty bottles because it may cause them to collapse during the test.

Many manufacturers rely on pressure decay testing—an effective and reliable method of inspecting empty containers.

Contact us for more information regarding our pressure decay leak testing method for your empty rigid containers, or call us at 1 (800)-325-8717 with any questions about the right solution for your application.

How Is Pressure Decay Used to Test Empty Containers?

The typical leak tester is installed downstream of the blow molder on the line and uses a three-step process for empty bottle inspection.

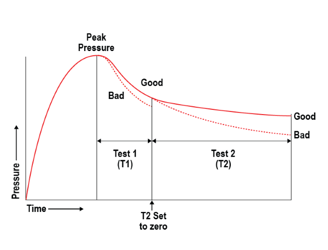

As the empty container enters the leak tester, a probe is extended to create a leak tight seal on the container opening. The tester fills the empty container to the test volume’s desired pressure, continuously monitoring the pressure level. If the target pressure range is not achieved within a pre-defined time the product is categorized as ‘reject’ for a ‘gross leak’. If the pressure is achieved, the tester records the peak value and moves to step 2.

As the empty container enters the leak tester, a probe is extended to create a leak tight seal on the container opening. The tester fills the empty container to the test volume’s desired pressure, continuously monitoring the pressure level. If the target pressure range is not achieved within a pre-defined time the product is categorized as ‘reject’ for a ‘gross leak’. If the pressure is achieved, the tester records the peak value and moves to step 2.- The tester measures the pressure drop from the peak value over a defined initial time (T1), and calculates the pressure change as a percent loss from the peak. It is normal for there to be a loss of pressure in all containers, and when the percent of pressure loss is greater than a pre-defined limit, the product is categorized as ‘reject’. If percent loss is lower than the limit, the test moves to step 3. This step can be used as stabilization time for flexible containers when longer test times are available.

- In an optional third step, the tester measures the pressure drop from T1 to the end of the test (T2), calculating the change as a percent loss between T1 and T2. If the percent of pressure loss is beyond a pre-defined limit, the product is categorized as a reject. If the percent loss is lower than the limit, the container is categorized as ‘good’. This final test offers detection of the smallest leaks.

Maintaining Accuracy During Empty Container Testing

Several factors determine the length and accuracy of pressure decay tests. Longer tests, for example, typically have higher sensitivity than a short test. Large volume containers also require more test time than a smaller container to detect small leaks. Maintaining a consistent temperature along the production line is also essential; any temperature variations in the product can affect the accuracy of leak tests.

The final and perhaps most crucial factor is the quality of your leak testing equipment. Low-quality leak testers may miss holes on the smaller end of the typical empty container spectrum, which is 0.004” (0.1mm) to 0.020” (0.5mm). When you’re considering the right leak test solution for your containers, consider ALPS. As the leader in empty container leak testing, our products are engineered to exceed customer expectations and ensure container quality.

To learn more about pressure decay leak testing, read our blog, Pressure Decay Leak Test: Why it is ideal for empty container leak testing.

Empty Container Leak Testing Solutions from ALPS

The top 10 bottle blow molders in North America trust ALPS pressure decay testers for their quality defect inspection. Our testing solutions are ideal for empty containers of varying sizes, ranging from 3cc eyedroppers to 5-gallon edible oil bottles.