Industry Leading Inspection Methods

Monitor and improve plastic container production.

Monitor and improve plastic container production.

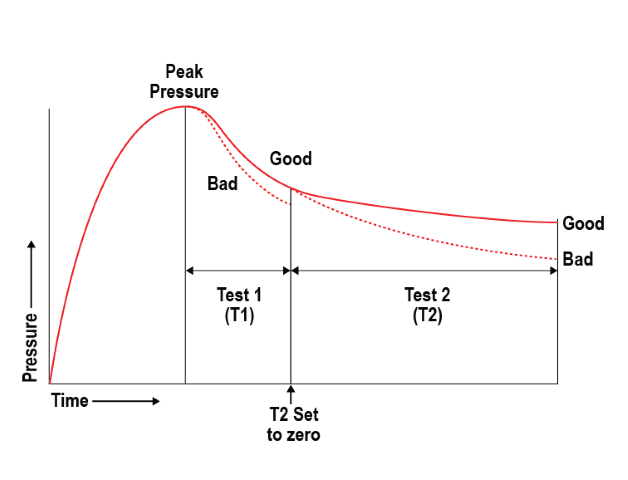

Standard ALPS inspection leak detection systems incorporate non-destructive pressure decay leak testing.

In empty container leak testing, pressure decay is the dominant method for in-line leak test solutions. The container opening is sealed for purposes of the test and leakage outside of this volume to the atmosphere is detected and rejected. Vacuum decay can be used if there is a requirement to verify that the container can hold a minimum vacuum level (e.g. for products that are vacuum packed).

In filled and sealed container leak testing, vacuum decay is the most common method for in-line and off-line leak test solutions. For verifying seal integrity, an enclosed test volume is created around the product's sealing area. For verifying seal and package integrity, the entire part is enclosed into a chamber. In each case, leakage into this enclosed volume is detected.

ALPS leak testing machines can offer additional testing options, such as bottle height and choked neck inspection.

Learn more about auxiliary inspection methods.