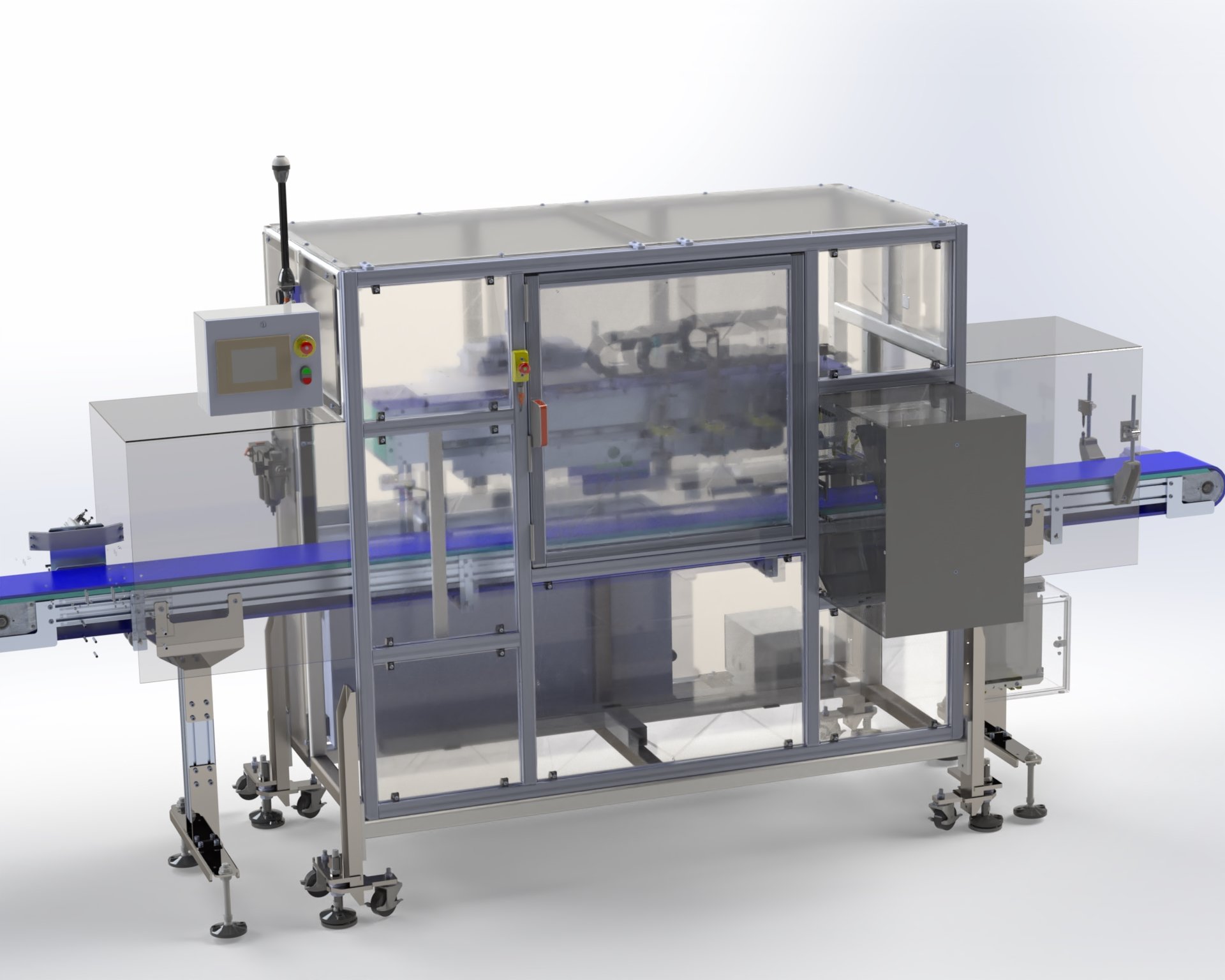

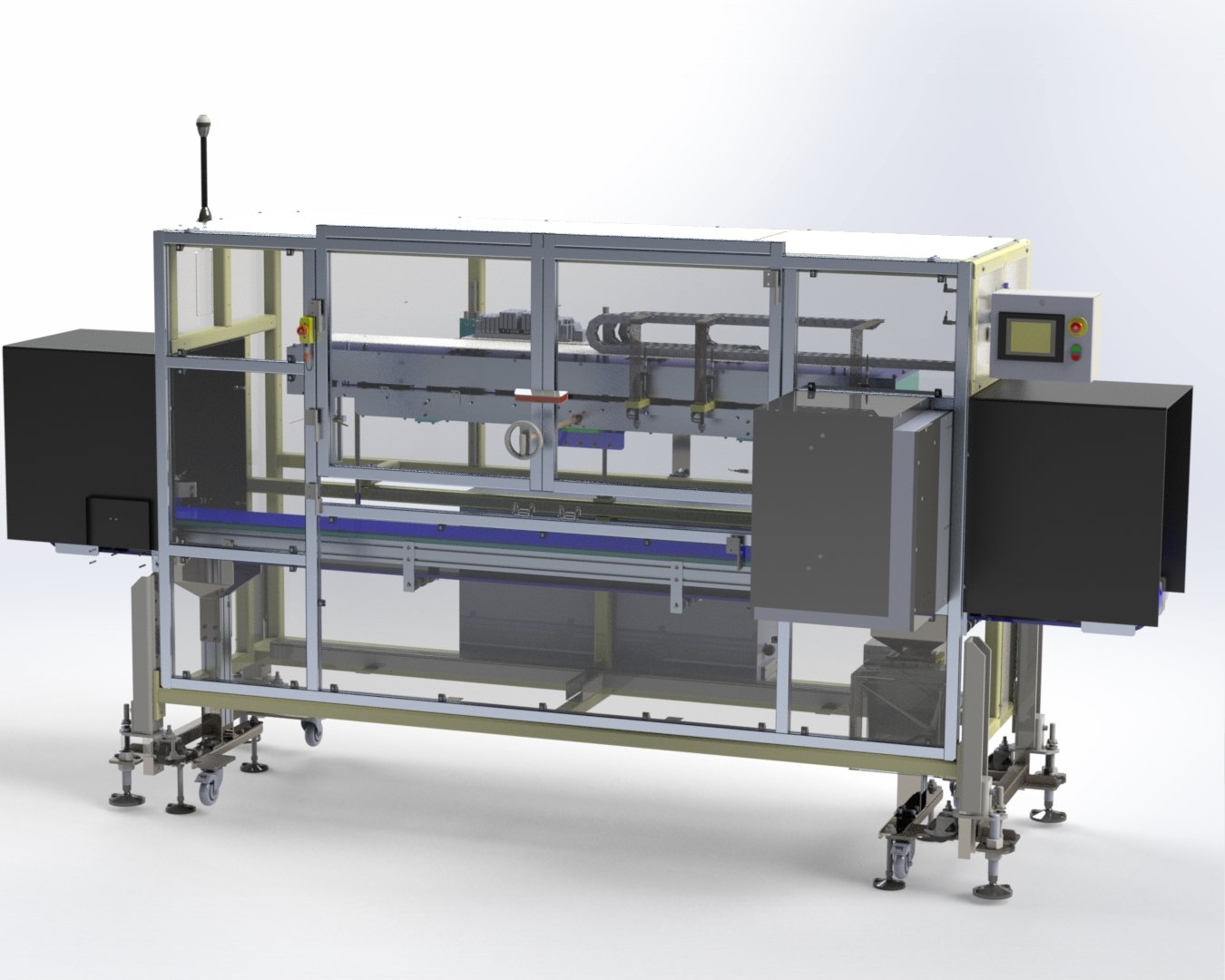

FlexPitch Multi-Head Container Leak Testing System

Offering 100% inspection for leaks and top seal surface defects.

Offering 100% inspection for leaks and top seal surface defects.

Looking to leak test smaller containers? The new FlexPitch® Duo might be the right choice for your production line. Learn more about FlexPitch Duo now.

Standard Frame Size

Extra Large Frame Size

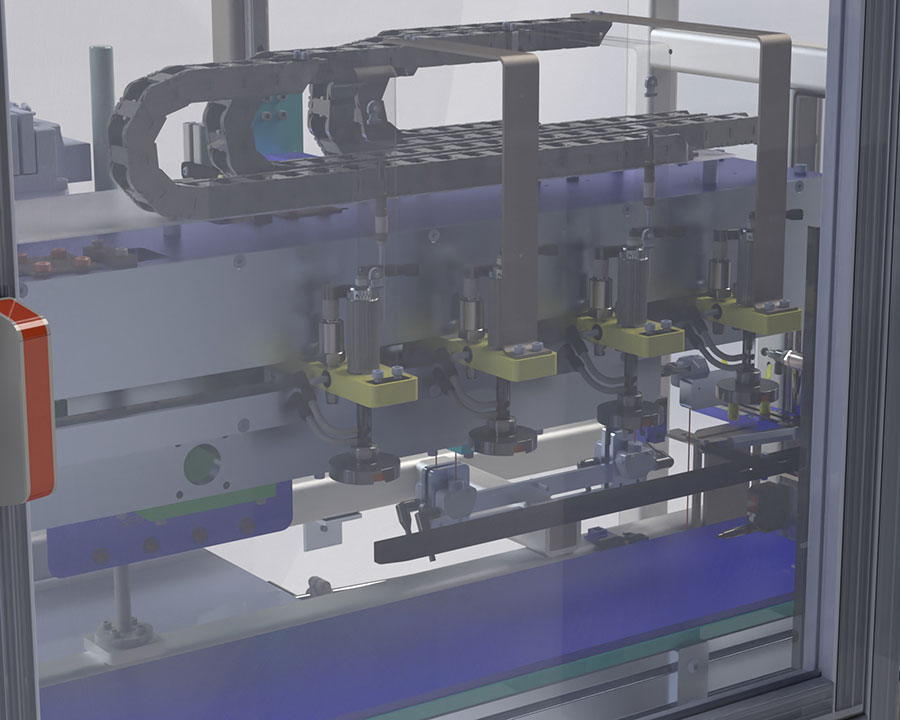

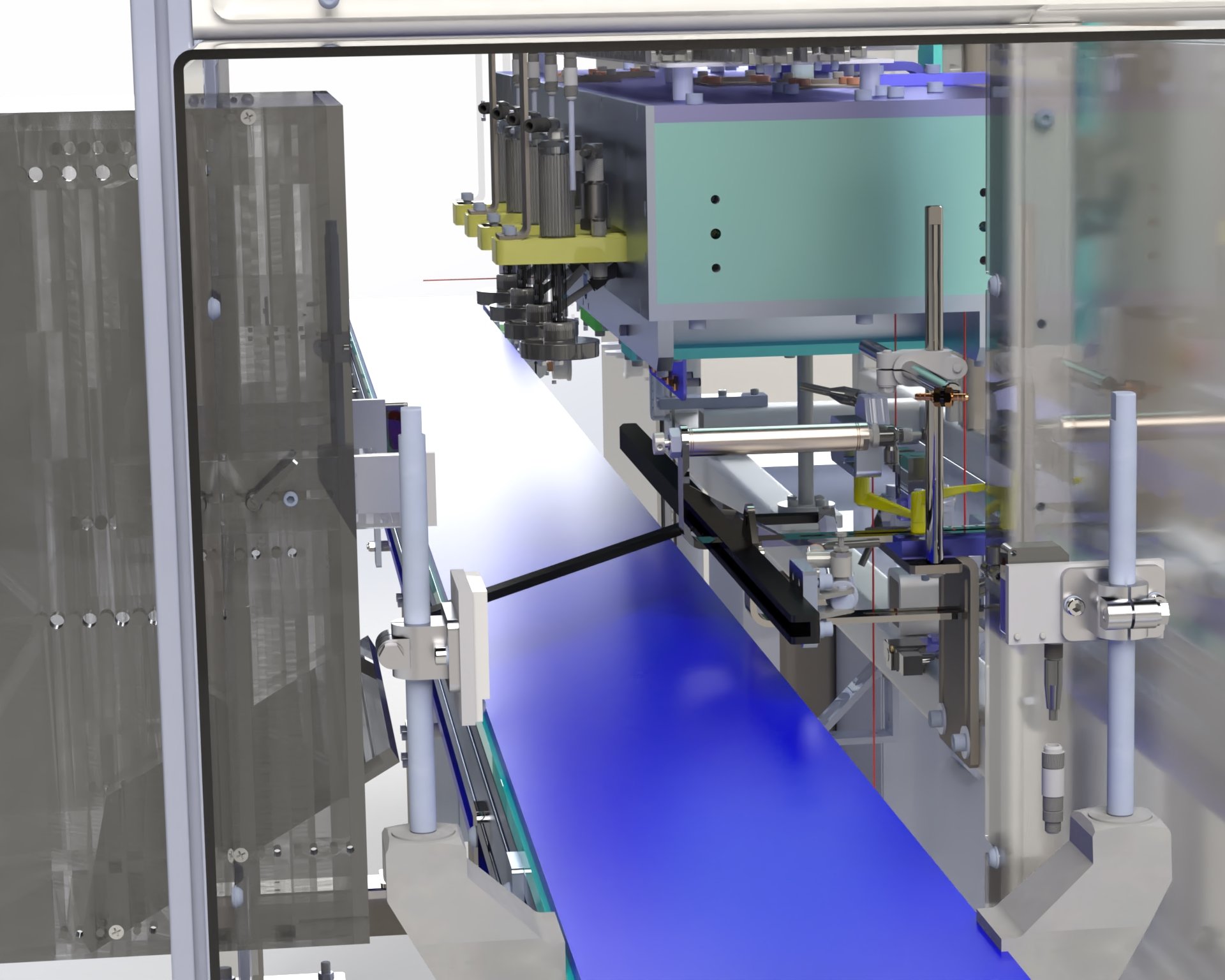

Test Heads

Conveyor

The FlexPitch is a fast, tool-less, multi-moving head leak tester with the flexibility to test a wide range of empty containers. The machine operates without a timing screw, which significantly reduces the cost for tools, as well as, the time it takes to perform a changeover. This results in a reduced cost to run additional container types.

The innovative design maximizes flexibility as test heads can be pre-set to the required pitch enabling fast changeover between containers of varying diameters. It is particularly suitable for difficult to handle container shapes including:

Features of the FlexPitch include:

Common applications for empty container inspection using the FlexPitch multi-head moving head leak tester include:

To discover your ideal leak detector, fill out a form confirming your requirements and an ALPS expert will be in touch.